I used a stubby flat head screwdriver and a ¼” ratchet driver with a 11/32 socket to remove these. I also had to remove the bracket for the window lever operator at this time.

Once the bracket was disassembled, I could open the window further to get to the last of the screws. I was careful not to over extend the window hinge; I was afraid of bending stuff too far. The stubby screwdriver came in really handy here.

The screen is just stretched across the frame and tucked into a little channel to tighten. I used a plastic putty knife to tighten things up because it was nearby, but a screen rolling tool would have been nice for screen replacement.

I think that anyone who is handy could replace the screen, but if you are nervous, just take it to a hardware store. I don’t think it will break the bank.

Once the aluminum pressure strips were removed, I found a variety of goop sealing the glass in place.

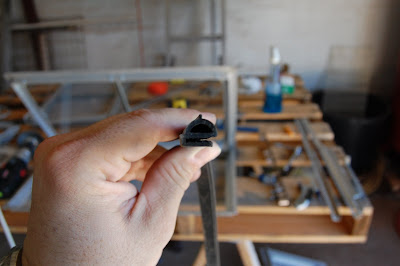

The little window by the upper bunk had old vinyl weatherstrip, some had the original ¼” putty bead, some had silicone, and some had a combination of silicone and putty.

This can be tricky; I used a razor blade to free the glass from the frame.

Go slowly and be careful or this can happen:

Which makes me unhappy.

I made three trips to the hardware store that day. Also, when measuring for replacement glass, give yourself about ¼” slop for both measurements. I suggest this for two reasons: for one, none of these frames are particularly square, and for two, when the glass is tight and you live in a place like

For weatherstripping, I decided to use the silicone rubber Hehr Standard Glass Seal from Vintage Trailer Supply that looks very similar to the vinyl on the small window. I ordered three 24’ rolls for my windows for $72 total. I also ordered two 24’ rolls of silicone rubber Hehr Backframe Gasket to replace the old brittle seal for $80 total. For the Jalousie window over the kitchen sink, I ordered a 16’ roll of Pile Weatherstripping for the edges for $6, vinyl weatherstripping for the bottom edges of the glass for $5, and silicone discs to help hold the glass in place for $5. I also ordered three rolls of butyl putty tape for $15 total. Okay deep breath, I dropped some serious coin at VTS, but I feel like sealing up these windows will prevent a lot of trouble down the line. And their prices are hard to beat, their shipping is reasonable and their customer service is stellar. No, they don’t pay me, but I did get a free hat because I ordered a pile of stuff. You can get replacement nuts and bolts, lever arms and lots of other Hehr window goodies at VTS as well.

Now back to the windows. After the glass was out, I cleaned them up with a fine wire brush chucked up in the drill.

This didn’t give me the mirror finish that I got on the z stripe, but I got a nice brushed aluminum look. Once cleaned up, I cut the glass seal to fit, dropped in the glass and bolted the aluminum strips back in.

Many of the machine screws were pretty rusty, so I replaced them with 10-24 x 3/8” screws and lock nuts.

In hindsight I would have used the 8-32 screws and nuts from VTS, it was a bit snug getting the 10-24’s in the holes. I reused the original washer head screws on the sides because clearance was an issue and the washer heads had a lower profile. I removed the old brittle backframe gasket, it just pulls right off.

I then cut the backframe gasket to fit and put new putty tape at the top.

If you have trouble getting weatherstrip to stay in place, this is a time when it is okay to use silicone, a small bead inside the gap, to help hold it on the aluminum.

Now for reinstallation. This is where it gets tricky. The wise guys at the Shasta plant didn’t particularly care where screws went; for example, some went into wood,

and some just barely into wood, cracking it.

I would have been more concerned, but there are about 25-35 screws per window, so they still managed to stay put. I tried to angle screws when reinstalling to hit something solid. I used size 6 x 3/4” aluminum pan head square drive sheet metal screws from McFeely’s Fasteners online, to attach the windows and to replace other screws used on various places on the body of the camper.

I ordered 500 for $43. I also ordered 300 size 8 x ¾” aluminum pan head square drive sheet metal screws for $27 for the drip edge that runs the full curve on both sides of the camper. You could also use stainless steel screws in the same sizes for about 2/3’s of the price. I would avoid the temptation of the nickel-plated screws that are cheap at the box stores, because they will rust eventually. Personally, I just liked the way the aluminum square drive screws looked. Once I got the first window in, the rest followed fairly easily, but it took most of the weekend to do it. For the drip eyebrows above each window, I used butyl tape and the size 6 screws, as well.

Most of my windows were regular Hehr pop-up style windows, but I do have one Jalousie. Replacing the pile along the edges was really easy, I just grabbed the end with a pair of pliers and pulled; it slid right out. I had to persuade the new pile in with an awl, moving it a few inches at a time, but the new pile went in with little difficulty. The discs slid right into the fingers along the edges that hold the glass. This is all aluminum so I tweaked things with a pair of needle nose pliers as I went. The vinyl weatherstrip for the bottom of the glass was a great fit; I used clear silicone as an adhesive. I dropped the ball on this window, and forgot to take pics as I went.

If there are questions about anything in particular that you feel I haven’t covered, shoot me an email, or comment.

So, if you are following along, so far we have:

Trailer $900

Bearing Repack $100

Steel $10

Sealant $10

Fan-Tastic Fan $140

Three Sheets 1/8 Birch $50

3M Polish $18

Buffer Pad $12

Mothers Aluminum Polish $8

TSP Cleaner/Paint Prep $8

Rollers, brushes and trays $30

Frog Tape $10

Etching Primer $5

Goo Gone $3

Paint 3 Gallons $98

Foam $250

Upholstery Fabric $510

Curtain & Pillow Fabric $80

Glass $50

Glass Seal $72

Backframe Gasket $80

Pile Weatherstrip $6

Vinyl Weatherstrip $5

Silicone Discs $5

Butyl Tape $15

Screws $70

Bringing our tally to: $2,545

Until next time dear readers, shasta la vista...

Awesome, you are my hero!! Thanks for posting all the details and with great photos too.

ReplyDeleteAmy in Alaska

Very helpful :) Can't wait to read the rest of your blog. We purchased a 1964 Shasta from Craigslist for $500 and although we knew it would be work to restore it I have to admit we didn't know it would be quite this much work! But we are actually enjoying it.

ReplyDeletehttp://melinda-cook.blogspot.com/

I love seeing your restoration. I have a 1962 Airflyte. One question related to kids...where do you put them for sleeping? I have a 2 year old. Last year we brought along a porta crib so we had no room to walk around. Now she is more mobile and not sure about sleeping arrangements. Also, did you address leaky roof vent and repair inside and out? Thank you, EL

ReplyDeletewhere did you find the glass seal i can't find any thank you

ReplyDeleteYou're posts are so good...we are purchasing a 1966 FAN.It has great bones and we think it needs a few repairs...but allover pretty good. Thanks for your detailed budget points and repairs ...we will be accessing your blog!

ReplyDelete